Containerized Industrial Water Chiller

The containerized industrial water chiller can offer cold or ice water of constant temperature, flow, or pressure. No matter how low the outlet water temperature is, or how big the cooling temperature difference is, our 4 grades of cooling methods will definitely offer a perfect cooling solution.

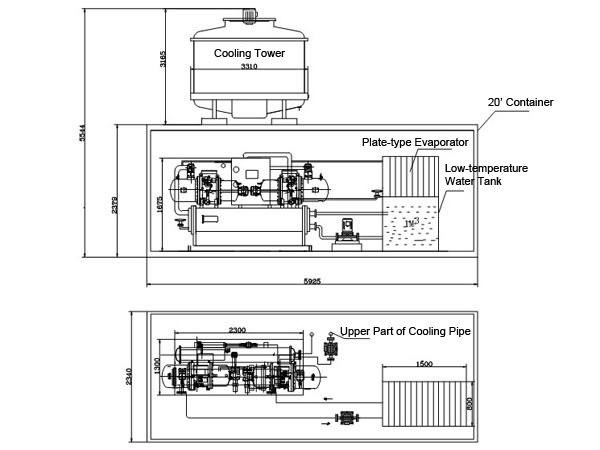

Sketch Map of 20 feet Containerized Chiller

Grade One Cooling

An evaporative condenser is applied to make use of the natural evaporation and cooling of water. Grade one cooling method can cool above 45℃ water to be 36℃ water. And only a small amount of power is needed.

Grade Two Cooling

Plate type or shell-and-tube evaporator which can cool water from 36℃ to 15℃ is utilized. The evaporative temperature is controlled at 10℃ or so, that's because higher evaporative temperature can ensure a better energy efficiency ratio of compressor. The maximum energy efficiency ratio of compressor is 4.2kw/kw.

Grade Three Cooling

This cooling method applies the plate type or shell-and-tube evaporator that can cool 10℃ water to 4℃ water. A pressure regulating valve is used to keep the constant evaporative temperature of +0.5℃. Therefore, high temperature difference inside the evaporator can be achieved to make sure a good heat exchange effect. Besides that, the evaporator has no frozen cracks.

Grade Four Cooling

A special immersion type plate evaporator with air antifreeze technology is used. It won't have any frozen cracks. By applying a pressure regulating valve to control the evaporative temperature at -5℃, the evaporator can lower the water from 4℃ to below 0.5℃.

Features of Containerized Industrial Water Chiller

1. Our containerized industrial water chiller is customized based on the client's requirements. Aside from the automatic PLC control system, it also applies the domestic and overseas well-known parts. Thus, it comes with convenient, stable operation, and excellent quality.

2. The self-contained refrigerating system enhances the operational reliability.

3. The water chiller uses the imported economical semi-enclosed twin-screw compressor that is characterized by high energy efficiency ratio, reliable operation, and long service life.

4. The star-delta starting adopted by the compressor under the minimum load, has effectively lowered the starting current and decreased the impact on the power grid.

5. The flexible energy adjustment design makes the machine energy continuously adjustable among 25% to 100%. It not only makes sure the compressor efficiency, but also maximally helps you save the operational cost.

6. By applying large high-precision touch screen, industrial intelligent controller, and advanced computer control system, the containerized industrial water chiller has the following multiple control functions:

a. Multiple Protection Function: The damage resulted from over temperature, default phase, reverse phase, high or low pressure, oil pressure, etc., will be avoided with effect.

b. Automatic Power-off. The automatic unmanned operation management can be realized.

c. Multiple password settings prevent the equipment from being shut down or damaged because of the accidental factors.

d. Such functions as remote information collection, fault diagnosis, operation inspection and control, etc., are realized via the local area network or internet.

7. The containerized industrial water chiller adopts the internationally well-known brand expansion valve, solenoid valve, one-way valve, or other electric control elements. Consequently, the high working efficiency is guaranteed.

8. The dual-cycle coupling refrigeration system with an economizer is used to improve the machine service capacity and energy-saving efficiency.

9. This machine is suitable for the environmental refrigerants including HFC134a, HFC407C, and so on. It suits to the international environment protection requirements.

10. A perfect, reliable running mode used in winter or transition season is available. It controls the minimum condensing temperature, through the frequency conversion of cooling tower or cooling water pump, or through the ratio adjustment of cooling water flow.

11. Our containerized industrial water chiller makes full use of the low-temperature cooling water, saving more energy.

| Brand of Containerized Chiller: SHARE | |||

| Operation Condition of Water Chiller | |||

| 1. | Maxi. Environment Temperature | +55℃ | |

| 2. | Relative Humidity | 0.85 | |

| 3. | Water Temperature | 2-5℃ | |

| 4. | Power Supply | 3P / 380V / 50HZ | |

| 5. | Refrigerant | R22 | |

| 6. | Compressor | Semi-hermetic screw compressor | |

| 7. | Evaporating Temperature | 2℃ | |

| 8. | Condensing Temperature | 38℃ | |

| 9. | Cooling Method | Water cooling / evaporative cooling | |

| Performance Parameters | |||

| No. | Item | Data | |

| 1. | Product Name | Water chiller | |

| 2. | Cooling Capacity | It is up to the client's demand | |

| 3. | Noise Level | 74dBA | |

| 4. | Compressor | Type | Semi-hermetic screw compressor |

| Brand | Hanbell / Bitzer | ||

| 5. | Cooling Method | Water cooling or evaporative cooling | |

| 6. | Electrical Element | Schneider / LS | |

| 7. | PLC | Siemens / LS | |

| 8. | Control System | PLC Process Control | |

| 9. | Water Supply Temperature | 2-5℃ | |

| Brand of Main Parts | |||

| No. | Parts Name | Brand Name | |

| 1. | Compressor | Hanbell / Bitzer | |

| 2. | Water Cooled Shell & Tube Condenser | Jiangche | |

| 3. | Dry Type Shell & Tube Condenser | Jiangche | |

| 4. | Cooling Tower | LINKE | |

| 5. | Solenoid Valve | DANFOSS | |

| 6. | Expansion Valve | DANFOSS | |

| 7. | Dry Filter | ALCO | |

| 8. | Liquid Line Sight Glass | DANFOSS | |

| 9. | Pressure Controller | DANFOSS | |

| 10. | Oil Pressure Differential Controller | (Hanbell) / (Bitzer) | |

| 11. | Low Pressure Gauge | REFCO | |

| 12. | High Pressure Gauge | REFCO | |

| 13. | PLC Control | LG (LS)/ Siemens | |

| 14. | Electric Fittings | LG (LS)/ (Schneider) | |

Related Names

Industrial Water Cooler | Liquid Cooling System | Water Chilling Equipment

English

English العربية

العربية Français

Français